The Advantages & Disadvantages of SMT Technology

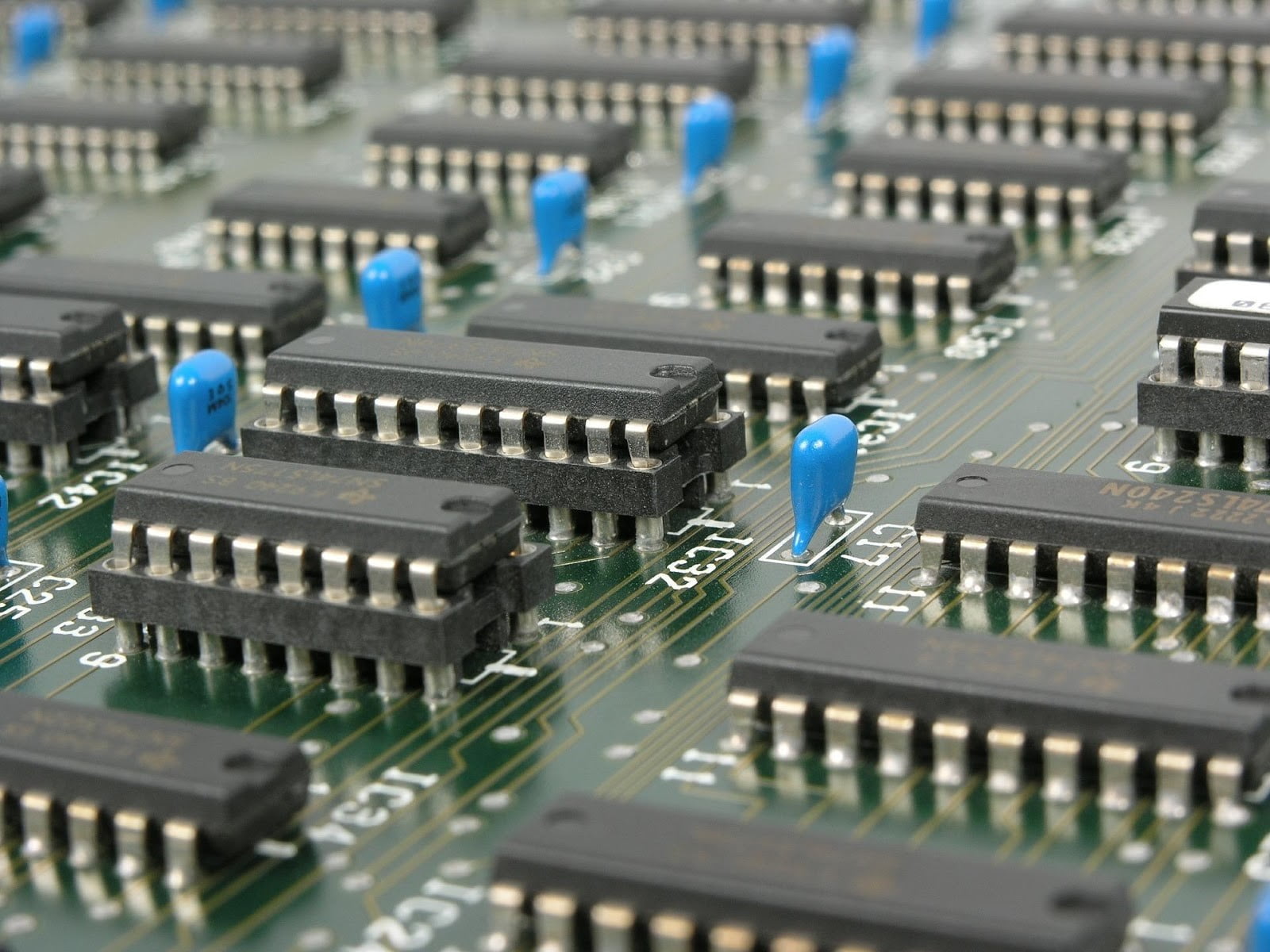

Surface mount technology is a type of method that has become popular over the years because of its smaller aspect and the ability to carry smaller components for electronic devices. Since the year 1980, SMT has been developed to replace an old method – the through-hole technology method that requires wire leads to holes in a circuit board (read more). Surface mount technology is an act of directly mounting wires to the circuit boards. The through-hole method was vastly replaced by SMT technology to further promote lesser cost on production.

Thanks to the innovation of experts towards ideas on how to have electronic devices carried conveniently by consumers, this type of technology has been developed. Printed circuit boards are soldered with wires to be operative on an electronic device. This process has gained a lot for the manufacturing business of electronic devices because of its convenience and lesser cost for production.

In the year 1960s, surface mount technologies have been developed by the pioneer worker who is IBM and was used on the first computers introduced to the world. It was widely used in the year 1980s and so years continuing. Surface mounting was called as “planar mounting” before it evolved to the common word used nowadays. Because of these methods developed over the years, we can now carry our laptops, cellular phones, headphones, etc. conveniently.

It became hassle-free and easy to use devices for us people. Remember when the first computers released were bulky, limited access, and needs a lot of other components to function? Thanks to the people creating SMT technology to simplify these products, we don't need to use those anymore. We can now enjoy a more convenient way to experience modern tech.

What Are Its Advantages to People

It's not just the end-users or consumers of the electronic devices that are enjoying its benefits but also the manufacturers of it. Listed below are some of the many points on advantages and SMT technology could offer:

Manufacturing companies can have lesser production cost

Production for components that are produced with the SMT technology method gives out the benefit of a lesser cost. Thus, it has a domino effect to other manufacturers as well. Lesser cost of raw materials means cheaper product prices assembled.

Lessens work by making drilled holes fewer than before

Printed circuit boards are drilled to fit wires to it, which makes the connection of it as a whole. You can read more here on why printed circuit boards need to be drilled: https://madhavuniversity.edu.in/drilling-printed-circuit-boards.html

Lowers time on producing its components

It is not only a big cut to the expenses that are incurred in making these products, but can also lessen the time being exerted in installing wires on a circuit board, thus it may mean that you can have a bigger production of these items.

Simplifies and fastens automated assembly

Though it may sound to be such a big investment for manufacturers of these items, it is all worth it as it is capable of producing more than several 136,000 of components per hour.

Excellent mechanical performance with regards to vibrations and shake conditions

One of the qualities it could offer is its sustainability and strength to withstand any conditions that may affect its overall performance

The things listed above are just a few of the many advantages it could offer to other manufacturing companies.

Disadvantages of Surface Mounting Technology

As always, every advantage affects disadvantages, but worry not because these can somehow be avoidable with proper planning and handling:

May not bear withstand high electrical loads

Some components generated a high level of electrical load or too much heat that cannot be mounted on SMT-produced boards because the solder to it will melt because of too unbearable heat.

Much more difficult to repair

Because fewer holes will be drilled on the circuit board, it may be harder to repairs as there are only small lead spaces available.

The soldered connections may not withstand the process

In all unfortunate moments, the compounds used on the potting application can somehow give harm to your soldered connections and may damage it during thermal cycling.

These are just some of the many things you can learn about its disadvantages.

All technology may have advantages and disadvantages, but it has always served its purpose to people and SMT technology is just one of the few improvements in the electronics industry.